MEP BIM Services in Lincoln

Introduction

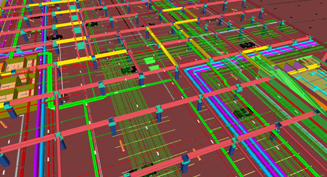

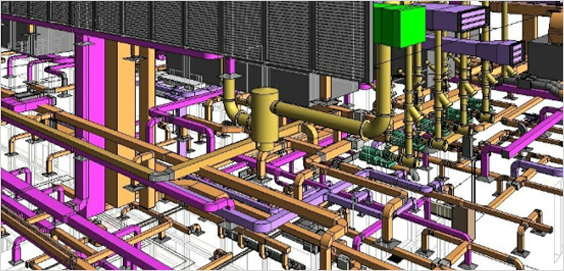

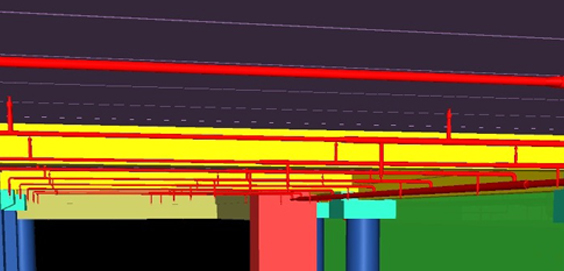

The integration of Building Information Modeling (BIM) in Mechanical, Electrical, and Plumbing (MEP) services represents a transformative leap in Lincoln's architecture, engineering, and construction (AEC) industries. MEP BIM services leverage advanced technology to create comprehensive, three-dimensional digital representations of a building's MEP systems, tailored to Lincoln's unique climate and building requirements. These models facilitate better design, construction, and operation by providing a collaborative platform where all Lincoln stakeholders can visualize, analyze, and optimize MEP components within the context of the overall building structure.

Our Lincoln MEP BIM Services include:

- 3D BIM Modeling, Coordination and Clash Resolution at LOD 300 & 400, adhering to Lincoln building codes

- Shop Drawings, Riser Drawings, Sleeve Penetration/Cut-out Drawings customized for Lincoln projects

- Block-out Drawings, Pre-Fabrication/Spool Drawings optimized for Lincoln's construction practices

- CNC Data integration with BIM Models, supporting Lincoln's local fabrication industry

- Quantity Take-offs (Pre-bid & Execution) reflecting Lincoln market prices

- Value Engineering & Design Validation considering Lincoln's energy efficiency standards

- As-Built model update & As-built documentation compliant with Lincoln facility management practices

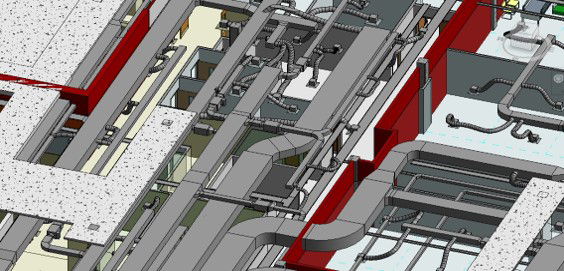

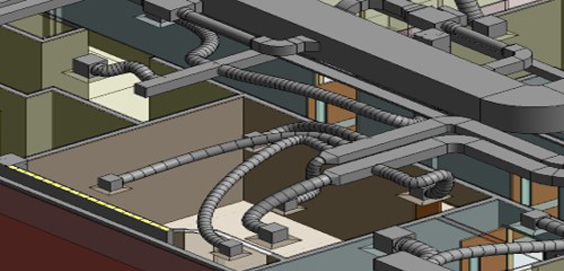

HVAC BIM Services for Lincoln's Climate

We offer virtual design development using 3D BIM models utilizing various sources of information including contract sets, design drawings, outline reports and equipment submittals, all tailored to Lincoln's hot and humid climate. A model of the HVAC framework, Hangers, Trapeze, and seismic restrainers is made and expanded utilizing data from Engineering, Auxiliary and other exchange and Utility sources, considering Lincoln's specific building requirements.

Our Lincoln-specific HVAC BIM services include:

- Mechanical Equipment Modeling as per submittal/cut-sheet provided, optimized for Lincoln's climate

- Mechanical Duct and Duct Fittings Modeling suited to Lincoln's air conditioning needs

- Duct Layouts designed for optimal performance in Lincoln's weather conditions

- Quantity Take-offs of Ducts, Duct Fittings, Mechanical Equipment, Diffusers, Grills, etc., based on Lincoln market availability

- Mechanical Components Modeling (with connections) adhering to Lincoln building codes

- Mechanical Equipment Enumerating with segments and isometric views

- Shop Drawings Preparation tailored to Lincoln construction practices

- Pre-Fabrication/Spool Drawings Preparation for efficient Lincoln-based manufacturing

- Rendered views of Mechanical Models showcasing Lincoln-specific HVAC solutions

- MEP Walkthrough simulations for Lincoln projects

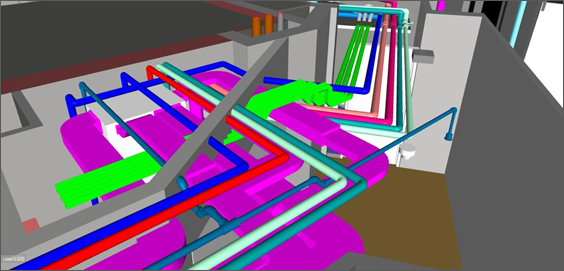

Plumbing BIM Services for Lincoln Buildings

Intec Infra specialists provide high quality services to meet the scope requirements of Lincoln projects with quick turnaround times for final deliverables:

- Process Piping, Steam and Boiler Piping designed for Lincoln's industrial needs

- Hot/Chilled water piping optimized for Lincoln's temperature extremes

- Sanitary, Vent System and Storm-water Drainage Piping tailored to Lincoln's rainfall patterns

- Compressed Air and Fuel/Medical Gas Piping compliant with Lincoln healthcare standards

- Sleeve, Hanger, Shop Drawings, Pre-Fabrication and Spool Drawings for Lincoln construction

- Quantity Take-offs for Plumbing Fixtures, Fittings and Accessories based on Lincoln suppliers

Electrical BIM Services for Lincoln's Power Infrastructure

Intec Infra handles Electrical Design support services, Modeling and Documentation services according to Lincoln standards for various stakeholders:

- Electrical lighting fixtures and layout modeling as per given schedules, considering Lincoln's energy codes

- Detailed light fixtures including volts, fitting type and lamps suitable for Lincoln's commercial and residential needs

- Cable trays in Electrical Model as per given drawings, adhering to Lincoln's electrical codes

- Schedules of circuits and panel boards optimized for Lincoln's power grid

- Shop Drawings Preparation tailored to Lincoln electrical contractors

- Pre-Fabrication/Spool Drawings Preparation for efficient Lincoln-based manufacturing

- Quantity Take-offs (Pre-bid & Execution) reflecting Lincoln market prices

- Rendering of Model with Lights showcasing Lincoln-specific lighting solutions

- Walkthrough of Electrical Model for Lincoln projects

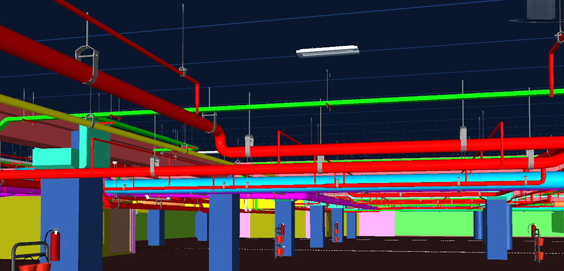

Fire Protection BIM Services for Lincoln's Safety Standards

Intec Infra is knowledgeable about understanding fire safety needs with respective design capabilities using BIM, all in compliance with Lincoln's strict fire safety regulations. Our specialists enhance the building model by including life security frameworks tailored to Lincoln's high-rise and commercial building requirements.

For Lincoln projects, we offer:

- Fire-fighting plans, 3D models and shop drawings compliant with Lincoln Fire Department standards

- Models and shop drawings to check for layout inconsistencies, code adherence, constructability and coordination issues specific to Lincoln buildings

- Drawings containing all data about Fire sprinkler systems like sprinkler heads, valves, pressure gauges, calculation plate, hangers, mains and branch lines required for quick and error-free site execution in Lincoln

Intec Infra Engineers model 3D fire protection systems and build an automated system for preparing Riser Diagrams, all customized for Lincoln's building types. Design validation of Fire Protection plans is done according to Lincoln principles and codes, as applicable. All Intec Infra staff are familiar with major software tools needed for Fire Safety Design support and associated Documentation, with specific knowledge of Lincoln's fire safety requirements.

By choosing Intec Infra for your MEP BIM services in Lincoln, you're partnering with a team that understands the unique challenges and opportunities of the Lincoln market. Our tailored solutions consider Lincoln's climate, energy codes, and construction practices, ensuring your MEP systems are not only efficient but also compliant with local regulations.